Sheet Metal Symphony: Crafting Precision in Manufacturing Processes in Chennai

Our team is dedicated to providing the best quality services and that you prioritize meeting your clients’ needs and exceeding their expectations. Working with clients from a wide range of industries shows your versatility and expertise in sheet metal fabrication.

The automotive, aerospace, and medical industries, in particular, often require high precision and reliable fabrication work. If there’s anything specific you would like assistance with or if you have any other questions, feel free to let me know.

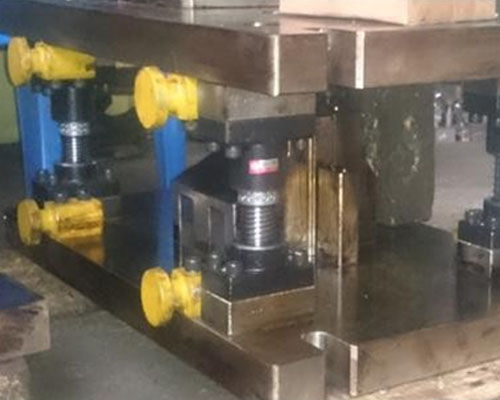

Sheet Metal Fabrication

We are capable of working with a wide range of sheet metal materials such as Stainless Steel, aluminum, and mild steel.

Sheet Metal Fabrication is offered exactly as per the design of clients with proper material inward inspection and also followed procedure of inspection during the process with assured excellent quality. Finished products inspected by highly trained engineers and also available to assist for better functionality and services as well as timely delivery. Sheet Metal on all types of material like machining components, mild steel, stainless steel, aluminium, brass, copper and exotic alloys etc.

We have advanced machineries to offer proper packaging without any kind of damage. We also offer to our esteemed clients all types of finishing like powder coating, plating, blasting and painting etc.

Benefits Of Using Sheet Metal:

- Sheet metal can be easily formed and manipulated into a variety of shapes and sizes, making it a versatile material for different applications. It can be cut, bent, stamped, and welded to create complex geometries.

- Despite its relatively thin profile, sheet metal exhibits excellent strength and durability. This makes it suitable for applications where structural integrity and load-bearing capabilities are essential.

- Sheet metal is lightweight compared to many other materials with similar strength characteristics. This is advantageous in industries such as automotive and aerospace, where reducing weight can improve fuel efficiency and performance.

- Sheet metal is often more cost-effective than other materials, especially in large-scale production. Its efficiency in manufacturing processes, such as stamping and forming, contributes to lower production costs.

- Sheet metal is conducive to rapid prototyping. It allows for the quick and cost-effective production of prototypes and small batches, facilitating the testing and refinement of designs before full-scale production.

Transforming Sheets into Functional Masterpieces

Sheet metal can be easily fabricated using a variety of techniques, including cutting, bending, welding, and punching. This ease of fabrication makes it a preferred choice for manufacturers looking for efficient and flexible production processes.

Recyclability:

Sheet metal is highly recyclable, contributing to sustainability efforts in manufacturing. Recycling scrap metal reduces the demand for raw materials and minimizes environmental impact.

Conductivity:

Certain types of sheet metals, such as copper and aluminum, exhibit excellent thermal and electrical conductivity. This makes them suitable for applications in electronics, heat exchangers, and electrical components.

Many sheet metals, including stainless steel and aluminum, have inherent corrosion resistance. This property makes them suitable for outdoor applications and industries where exposure to harsh environments is a concern. Sheet metal can be finished in various ways, including painting, powder coating, and polishing, to achieve a desired aesthetic appearance. This is important in applications where visual appeal is a consideration, such as architectural elements or consumer products.

For Visit Google Maps